Optimize Amazon inventory management! Avoid stockouts & excess fees. Boost sales, ranking & profit with smart FBA strategies.

Amazon Inventory Management: A Practical Guide for FBA Sellers

Amazon inventory management directly affects your sales, ad performance, storage fees, and even your organic ranking. If you run out of stock, your listing can lose visibility and the Buy Box. If you overstock, Amazon charges monthly and aged inventory fees that eat into your profit.

More than 82% of sellers use FBA, yet many lose money because they don’t manage their stock properly. You’ve probably experienced it yourself: having capital stuck in slow-moving inventory or missing out on sales because a top SKU ran out.

This guide shows you how to forecast accurately, reorder on time, and clean up excess inventory. Ready to protect your margins and grow your business with less stress? Dive right in!

Key Inventory Metrics Every Amazon Seller Should Track

To manage your inventory well, you can’t just guess or reorder only when your stock is running low. You need to track the right metrics because they tell you exactly when to restock, how much to send in, and which SKUs are hurting your cash flow.

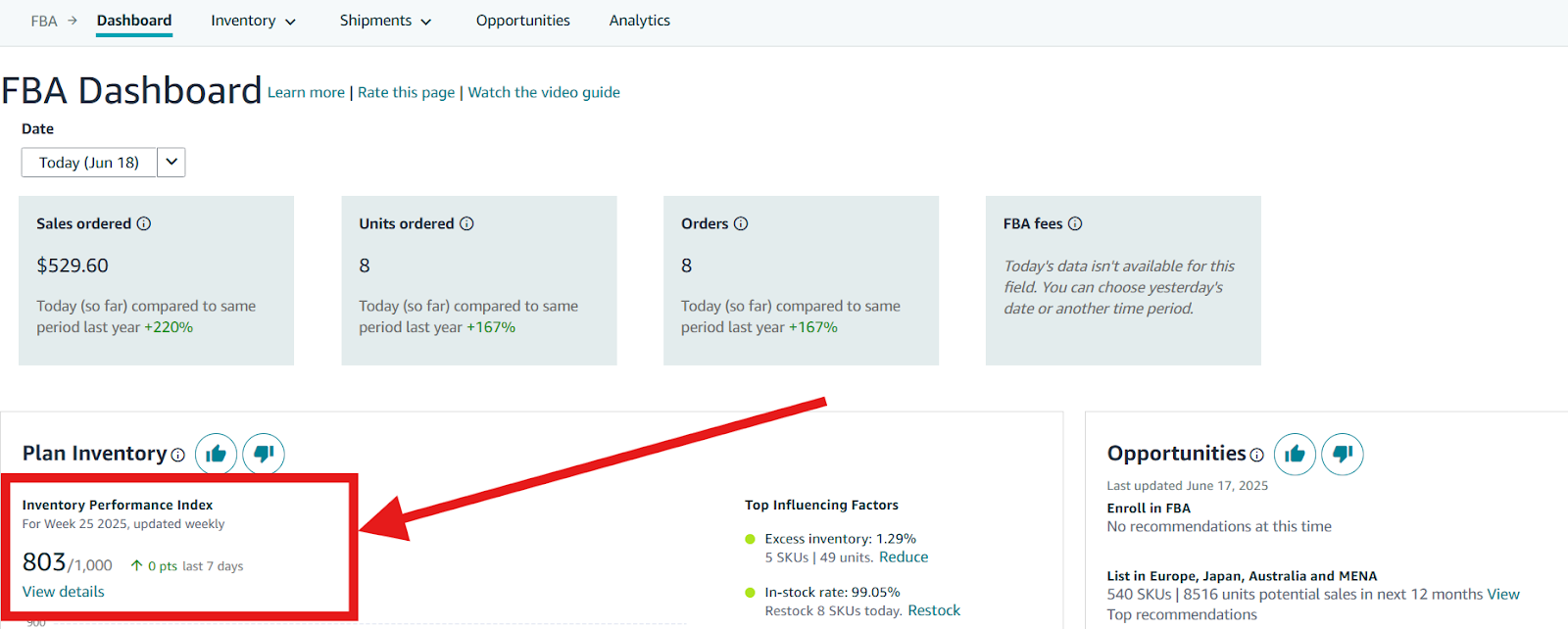

1. Inventory Performance Index (IPI Score)

This is Amazon’s scorecard for how well you manage inventory. It’s updated weekly and calculated based on four factors: excess inventory, sell-through rate, stranded inventory, and in-stock rate on popular ASINs.

If your IPI score falls below 400, Amazon may limit how much inventory you can send in. That means even if your product is selling well, you won’t be able to restock past a certain number units.

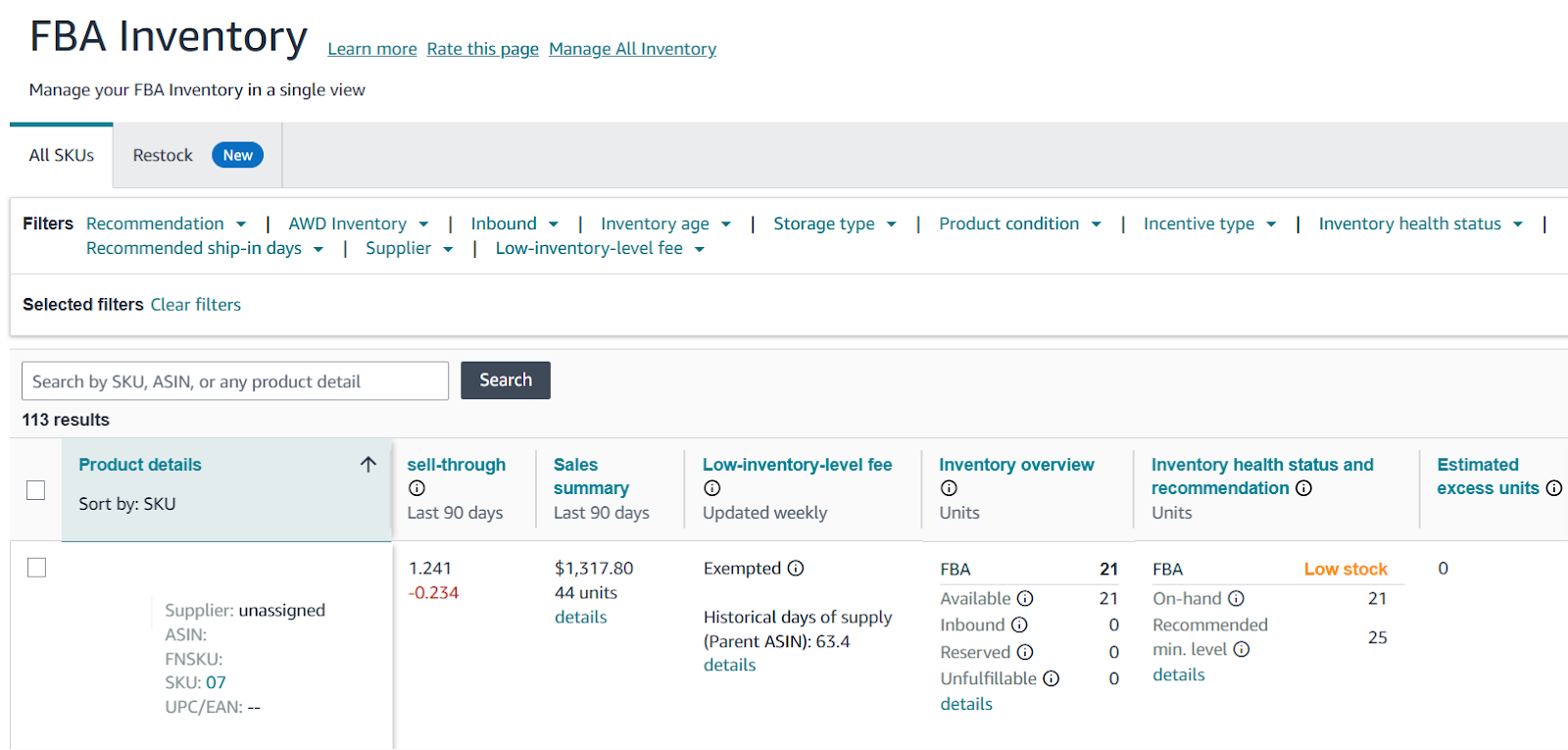

You can find your IPI score and detailed breakdowns in the FBA Inventory Dashboard.

2. Sell-Through Rate (STR)

This tells you how quickly your products are selling relative to how much stock you have in FBA.

STR = Total units sold over the last 90 days ÷ average units stored over 90 days.

If you sold 300 units in 90 days and had an average of 100 units stored, your STR is 3.0. That’s good. Amazon recommends keeping it above 2.0. If your STR is too low, you may get flagged for excess inventory, which lowers your IPI score.

You can find your STR on the FBA Inventory Dashboard, but you can also calculate it manually for individual SKUs to spot problem areas.

3. Days of Supply

This shows how long your current FBA inventory will last if your daily sales stay the same.

Days of Supply = Current FBA units ÷ average daily sales.

For example, if you have 600 units in stock and you’re selling 20 per day, you have 30 days of supply. For most SKUs, the sweet spot is 30 to 60 days. Less than that, you risk going out of stock. More than that, you risk paying more storage fees than necessary.

Amazon’s Restock Inventory tab gives you a rough projection, but tracking this manually for your top SKUs can help you make smarter restock decisions.

4. Stranded Inventory

Stranded inventory is stock sitting in FBA with no active listing. That means customers can’t buy it, but you’re still paying storage fees.

Your inventory could be stranded due to a listing error, price violation, or brand gating, and leaving even a few ASINs stranded for weeks can silently chip away at your margins.

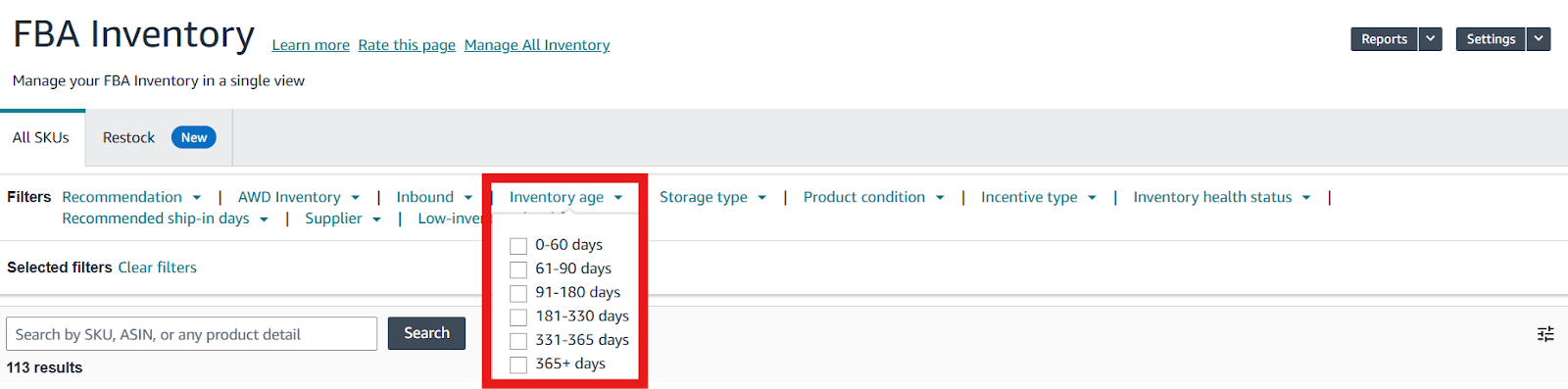

5. Excess and Aged Inventory

Amazon flags inventory as “excess” if it isn’t projected to sell in the next 90 days. Once it hits 181 days, it becomes “aged” and attracts higher monthly storage fees. After 271 days, the fees increase even more.

When you consistently track these metrics, making inventory decisions becomes a lot easier. You’ll know which SKUs to reorder, which ones to slow down, and when to run a promotion to clear space.

Common Amazon Inventory Challenges and How to Fix Them

Every Amazon seller, no matter how experienced, runs into inventory issues. It’s part of the business. What matters is how early you catch them and how quickly you act.

Here are five of the most common problems, and what to do when they show up:

1. Running Out of Stock Faster Than Expected

Sometimes, you order enough units, but sales spike due to a keyword ranking boost or a successful ad campaign.

If you run out completely, Amazon will bury your ranking and restrict how much you can send in later. Here’s how to fix it:

- If you have stock outside FBA (with a 3PL or even in storage), flip on FBM for that SKU. This keeps your listing live while you wait for FBA to restock.

- Cut back on ads or lower bids to slow velocity just enough to stretch what’s left.

2. Over-ordering and Getting Stuck With Too Much Inventory

Maybe you bought in bulk to lower unit costs or you overestimated demand. Now, Amazon is flagging your inventory as excess, and the aged storage fees are creeping in.

Here’s what to do:

- Run a coupon or cut down price short-term (10 to 15%) to bump up sales.

- Submit the product to Amazon Outlet Deals if you’re eligible.

- If you’re approaching 181 or 271 days in storage, create a removal order to avoid extra fees. Send the stock to a 3PL or hold it for a future promo.

3. Amazon Is Taking Forever to Check In Your Shipment

You shipped on time, but Amazon hasn’t received or made your stock available yet. Meanwhile, your listing is running low or already marked as “Currently unavailable.”

Here’s how to handle it:

- During busy periods (like Q4), always ship 7 to 10 days earlier than your normal restock timeline.

- Split shipments across multiple fulfillment centers when you can. This reduces risk if one location is backed up.

- If you’re out of FBA stock and check-in is delayed, switch to FBM short-term if you have inventory on hand.

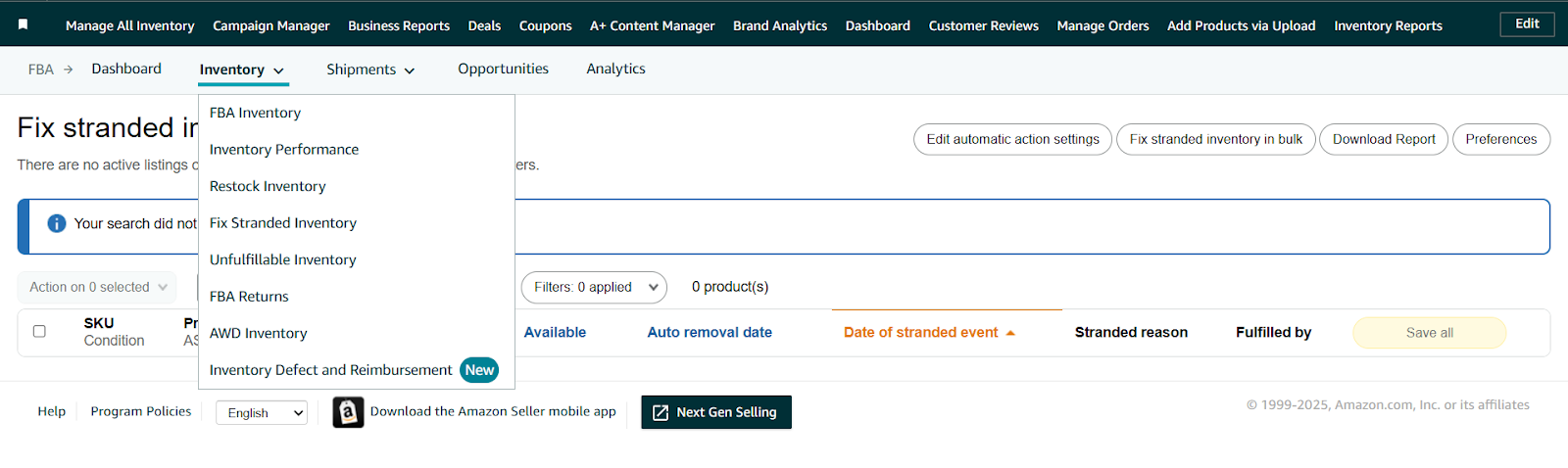

4. Inventory Getting Stranded Unexpectedly

This one hurts: your product is stored in FBA, but no one can buy it. Maybe the price is missing, maybe the listing got suppressed. Whatever the reason, you’re paying storage fees with zero sales.

Fix it like this:

- Go to Fix Stranded Inventory (Under FBA inventory in Seller Central) and resolve anything listed.

- If there’s no suggested fix, open a case and escalate it.

5. Too Much Capital Tied Up in Inventory

If you have thousands of dollars in FBA inventory, but very little cash to reorder bestsellers or run ads, here’s what to do:

- Identify SKUs that have more than 90 days of supply or are flagged as excess.

- Run aggressive PPC on just those SKUs for 7-10 days to increase velocity.

How to Build a Restock Plan That Actually Works

The biggest inventory mistakes often come down to poor forecasting. Either you order too late and run out of stock, or you order too much and get hit with storage fees.

A restock plan helps you order the right amount at the right time, without locking up cash or losing sales.

Step 1: Know Your Lead Time

Lead time is the total number of days between when you place an order with your supplier and when that inventory is available for sale on Amazon. It includes production time, shipping time, and Amazon check-in time.

For example, if it takes 10 days to manufacture, 25 days to ship, and Amazon takes another 5 to receive it, your lead time is 40 days.

Ask your supplier for realistic timelines and track how long Amazon typically takes to check in your goods. Then, set each SKU’s lead time to the longest realistic total under the Restock Inventory tab.

Step 2: Schedule a Weekly Inventory Check Day

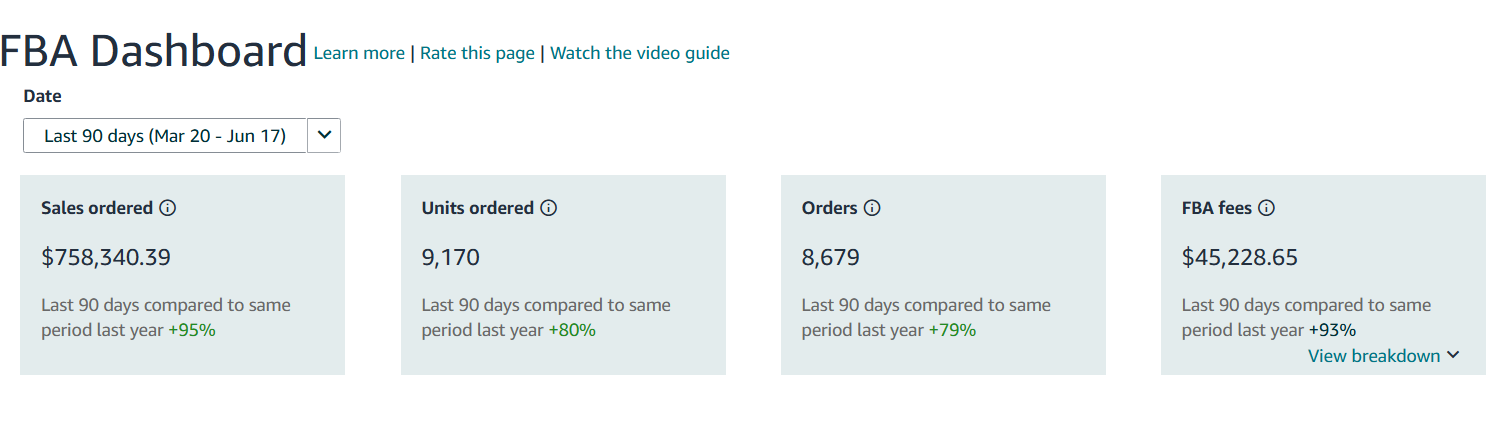

Choose one day each week to check your inventory using the FBA Dashboard.

Look specifically at:

- Days of Supply: If it’s close to or lower than your lead time (e.g. 40 days), you may need to reorder.

- Seasonal Demand Forecasts: Click the chart icon beside any SKU in the Restock Inventory Tool to see Amazon’s projected weekly demand and trends based on past seasonal patterns.

- Excess or Aged Inventory Alerts: These show which SKUs are sitting too long and costing you storage fees.

- IPI Score: If it’s trending down, review the specific breakdown (Amazon shows you what’s dragging it down).

Step 3: Use the Restock Inventory Tool to Reorder

Focus on your top-selling SKUs first. For each SKU:

- Check the “Recommended Ship Date”. If it’s near or overdue, act now.

- Look at the “Suggested Reorder Quantity”. This estimate is based on your lead time and sales history.

- Include a safety margin. If your lead time is unpredictable, or you’re heading into a peak season, add a buffer of 20 to 30% to the reorder quantity.

Conclusion

Inventory management isn’t just about avoiding stockouts or storage fees. It directly impacts your cash flow, ad performance, and how high your products rank on Amazon. When you get it right, you free up capital, stay in stock on your bestsellers, and grow without unnecessary stress.

Track your metrics weekly, use your FBA Dashboard proactively, and take fast action on excess or slow-moving SKUs. Small improvements here compound into bigger profits and a healthier business over time.